INSULATING OIL PROCESSING

To improve the quality of your transformer oil

REACH THE OPTIMUM OIL QUALITY WITH

DEGASSING, FILTERING AND DRYING

Does your oil analysis recommend a more economical solution for processing insulating oil rather than full oil regeneration? Or would you like to have your new transformer filled with insulating oil with modern and quality assured equipment? With our Mobile Processing Units (MPU) we can reliably fill your on-site transformers or degas, filter and dry your transformer oil during operation.

Thanks to the EOS® Service Units (MPU) of different sizes, the Electrical Oil Services experts can easily cover individual needs – regardless of whether the transformers are small, large or difficult to access or are used offshore.

Learn more about our mobile oil treatment units in our blog:

→ EOS® has Europe's largest fleet

.jpg?width=1100&height=620&name=Electrical_Oil_Services-EOS_4N9A4303_1100x620px_230907_retuschiert%20(1).jpg)

THE INSULATING OIL PROCESS INCLUDES

Dirty insulating oil is cleaned with µm filters and particles as well as solids are removed. This enables consistent performance of your transformers.

Moisture severely affects the dielectric properties. The EOS® MPUs offer a heating capacity of up to 200 kW to operate in cool temperatures. This allows us to ensure that your insulation medium is dry.

SERVICE FOR THE INSTALLATION, REPAIR OR MAINTENANCE

OF OIL-FILLED TRANSFORMERS

|

EOS® Mobile Processing Unit (MPU)

|

Our experts carry out the insulating oil processing with our EOS® Mobile Processing Units (MPUs). These are dedicated and specially equipped vehicle.

In addition to technical equipment, each MPU includes extensive analytical equipment for measuring specified parameters for the customer, such as breakdown voltage, interfacial tension and water content. These measurements are taken after each complete cycle of the transformer oil. The results of the measurements are recorded and used to evaluate the progress of the work. At the end, our customers receive a comprehensive final report.

Learn more about our MPUs: → Electrical Oil Services has Europe's largest fleet

Talk to our experts.

Schedule your individual consultation now!

WHEN IS THE MOST APPROPRIATE TIME FOR AN INSULATING OIL PROCESSING?

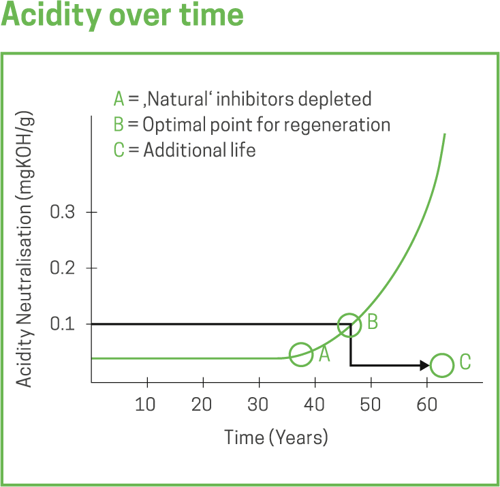

When a transformer is filled for the first time with new unused insulating oil, the acidity neutralisation figure will be <0.01 mgKOH/g. As the transformer ages, the action of heat and oxygen results in the oil oxidising as the oil’s “natural” inhibitors are depleted. Polar compounds in the transformer oil such as acids and earlystage sludge can be produced. It is these complex compounds which attack the transformer paper insulation, leading to weakening of the insulation and an inability to withstand closeup faults and through faults. Once the paper is damaged it cannot be repaired.

| EOS® recommendation: Ensure that your transformer oil is analysed regularly and conduct a cost-efficient insulating oil processing at the earliest stage possible, when acidity levels rise. |

TRANSFORMER OIL PROCESSING IS REQUIRED

Vacuum pumps carry out the drying process at a pressure level of less than 1 mbar and evacuate dissolved gases and water vapour so that the transformer oil regains its original quality. The process includes degassing, filtering and drying.

During the manufacturing process of a transformer, oil and paper absorb moisture from the environment. This must be removed in several stages and under vacuum before the transformer is put into operation. The procedure corresponds to the treatment used for repairs or maintenance.

HOW WE WORK

Insulating oil processing after repair and maintenance - effective and reliable against physical contamination

Vacuum pumps carry out the drying process at a pressure level of less than 1 mbar and evacuate dissolved gases and water vapour so that the transformer oil regains its original quality.

Filling new transformers - flawless and safe from the start

During the manufacturing process of a transformer, oil and paper absorb moisture from the environment. This must be removed in several stages and under vacuum before the transformer is put into operation. The procedure corresponds to the treatment used for repairs or maintenance.

EOS® BEST PRACTICE

Find out more about our work on these pages:

Steel production

Almost like NEW - investing in 20 neglected transformers

Objective: Ensure reliable production by extending transformer lifetime

Solution: EOS® insulating oil regeneration

Step-by-step deep cleaning for twenty 66 kV transformers

Combined heat and power (CHP) plant

Remove potentially corrosive sulphur from 230,000 litres of transformer oil

Objective: To remove the additive from the 1990s called DBDS

Solution: EOS® insulating oil regeneration

A total of 50 days of thorough deep cleaning to reduce the DBDS content from 100 ppm to <5ppm

Energy supplier

Extend the service life of transformers by 15 years without high investments

Objective: To deep-clean the insulating oil systems and to remove acids and sludge

Solution: EOS® develops refurbishment strategy for insulating oil regeneration during operation

Start of an era: Making sustainable asset management for transformers possible

.jpg?width=300&name=Electrical_Oil_Services-EOS_4N9A4303_1100x620px_230907_retuschiert%20(1).jpg)

Grid operator

Filling a 132 kV transformer after maintenance work

Objective: Remove contamination and achieve maximum dryness of the insulating oil

Solution: EOS® insulating oil processing

Restore safety with the Mobile Processing Unit (MPU) after warning message

Distribution system operator

Finding a solution when the newly ordered transformer is delivered late

Objective: Put the decommissioned transformer back into operation

Solution: EOS® insulating oil treatment

Drying the oil in the old transformer with extensive vacuum/heat treatment

Transformer OEM

Although stored in a dry atmosphere for a long time, the new transformer need to be installed in gas and steam turbine (CCGT) power plants

Objective: To generate a vacuum of less than 1 mbar at low cost and then fill the transformer with insulating oil

Solution: EOS® Mobile Vacuum Unit (MVU) and Mobile Processing Unit (MPU)

Enable cost-effective transformer installation

Steel production

Which transformer first? Prepare a professional transformer management system

Objective: Organise monitoring for each individual transformer at the production site to avoid failures

Solution: EOS® develops customised test procedure for regular sampling

Classify transformers according to importance for scheduled transformer oil analyses

Large power plant

Replace a 275 kV generator transformer and store the insulating oil temporarily

Objective: To store the company's own transformer oil for later re-filling into the new transformer

Solution: EOS® combines Mobile Processing Unit (MPU) and laboratory services with tanker lorries and storage tanks

Oil transport and storage off-site including consistent oil quality monitoring

Aluminium company

Sustainably remove 150,000 litres of insulating oil from decommissioned factory

Objective: Remove the insulating oil from the transformers and save the oil

Solution: EOS® organises and monitors the draining of the insulating oil in order to recycle it

Recycling of transformer oil: Collecting the used oil, improve the quality and return the oil to the market as recycled insulating oil

.jpg?width=300&name=Electrical_Oil_Services-EOS_4N9A4303_1100x620px_230907_retuschiert%20(1).jpg)

Distribution grid operator

25,000 litres of insulating oil from the main tank of a 132 kV transformer temporarily stored on site

Objective: To repair tap changers in an ecologically sensitive area and put them back into operation quickly after filling

Solution: EOS® insulating oil processing after interim storage of the transformer oil in an oil-rinsed, certified tanker truck

Insulating oil storage and 2-fold circulation directly and promptly on site