Building on six years of experience working closely with UK Distribution Network Operators, EOS has developed safe systems of work to mitigate risks associated with the treatment of live transformers.

Transformer oil regeneration, used as part of a well thought out mid-life refurbishment programme, has distinct advantages over traditional oil changes, namely:

- No or very little outage time

- “Deep Cleaning” effect removes more oxidation products from the paper insulation

- The oil stays in the transformer providing physical support for the paper insulation

- No covers to be removed for flushing

- Fewer vehicles on site so lower carbon footprint

- For 33kV transformers and above a more cost-efficient alternative to oil changes

- For any transformer a more effective option to oil replacement

- Less input from transformer asset owners

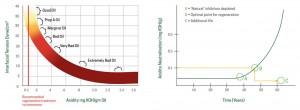

- Treatment restores oil to “as-new” condition

- Inhibitor added at the end of the work to further boost the oil’s oxidation stability

EOS has over 60 years’ experience when it comes to insulating oil reclamation and has spent considerable care and time to design and build regeneration units to our own specification, removing problems associated with earlier designs used around the world.

EOS Engineers are available to discuss your precise requirements, carry out a full site survey, assess oil test results and generally guide you down a trusted and professional path.

For more information on our products and services contact:

|

UK: Electrical Oil Services – EOS

|

Continental Europe: Martin Seipel VP Business Development Europe Electrical Oil Services – EOS

|

For more information on EOS please visit www.electricaloilservices.com; and for more information about HCS Group, please visit www.h-c-s-group.com.